Critical Characteristics

This process is undertaken in separate enclosed workshops for cleaning and inspection to avoid cross contamination.

Careful and complete dismantling is essential to conserve condition and to be able to correctly assess the viability of critical parts and their characteristics. Non-wearing or non-degrading parts such as housings and casings may be re-used to reduce materials, labour and energy content of the remanufactured item. Some items may be disposed of 100% such as seals, nozzles, washers, springs, circlips and retaining devices.

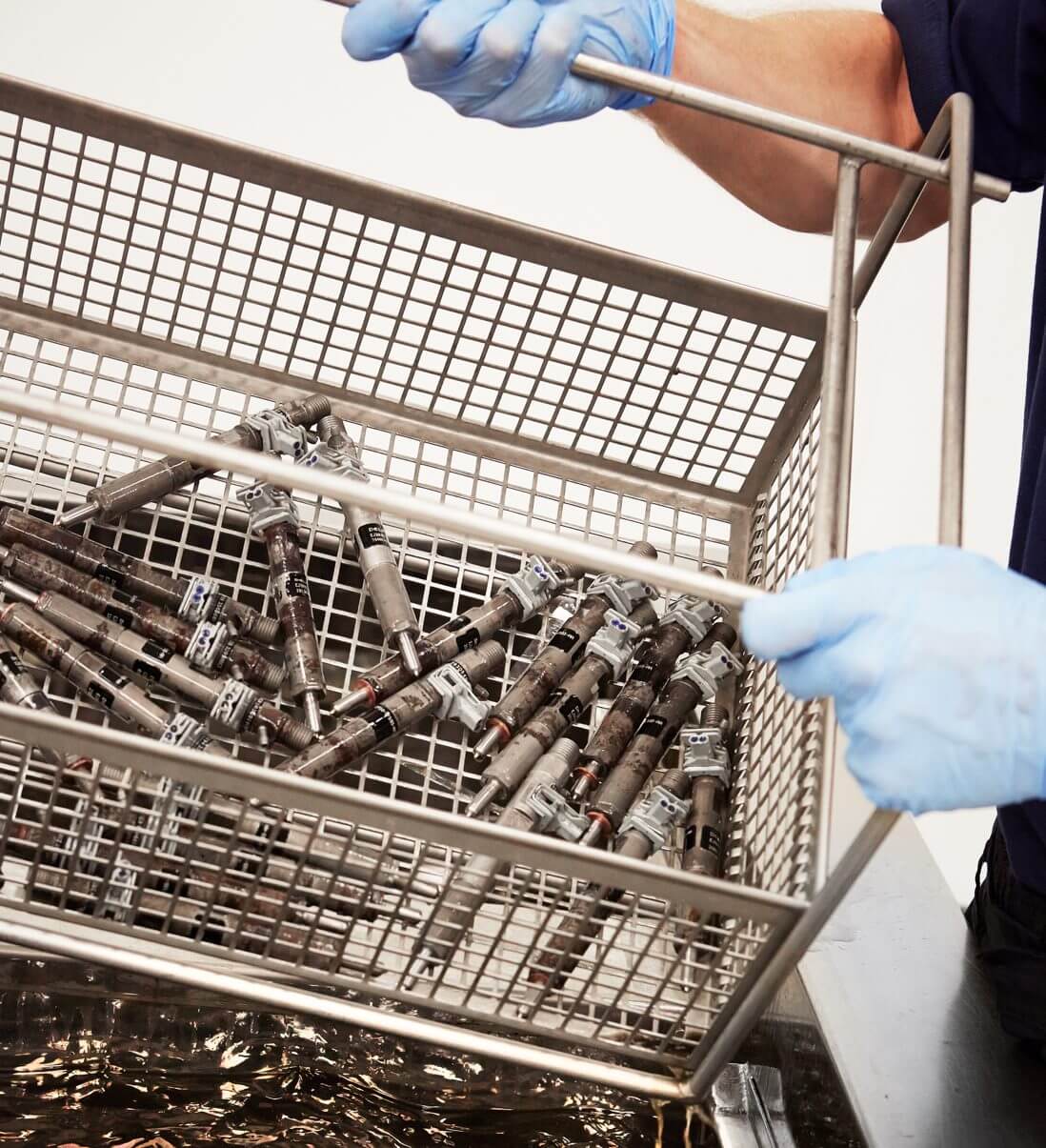

Once separated components are initially checked by visual inspection for obvious damage, deterioration or corrosion, if deemed potentially recoverable at this stage the items then proceed to a specific cleaning process for that part.

The cleaning methods include methods as ultrasonic bath technology, special media blasting, solvent washing, hot detergent machines and manual detailing. After cleaning items are checked by NDT methods for cracks and imperfections, parts are also checked for wear or conformance to dimensional criteria as required.

Once re-useable items are cleaned, inspected and approved they are designated for inclusion in production and kitted with new components for assembly.

Critical Characteristics