Remanufacturing Standards

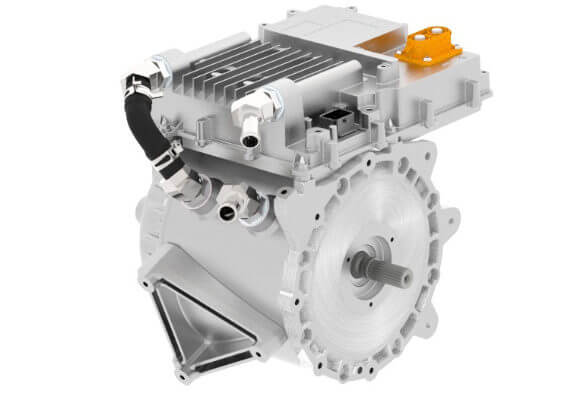

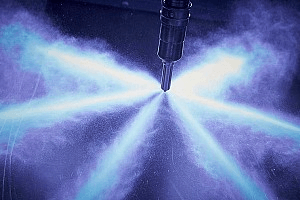

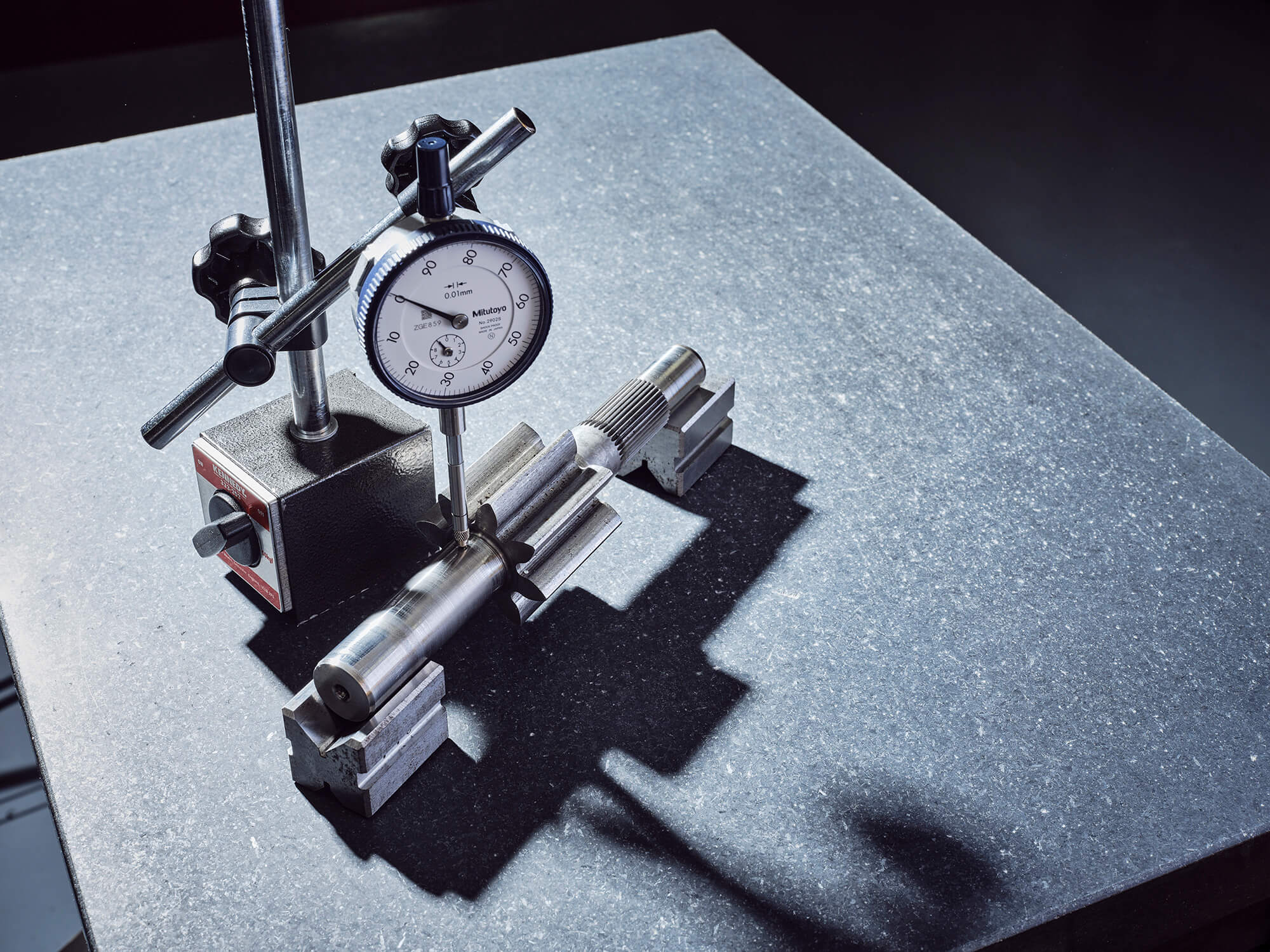

Engine remanufacturing combines all the Carwood core competences of diesel, turbocharger and rotating electrics engineering to output a fully assured complete engine in accordance with BS8887-220. This British Standard specification requires that the performance and the warranty is at least equal to that of a new product. All engines are dismantled to individual constituent parts and inspected meticulously against original specifications. As well as dimensional checks, NDT processes are used to detect cracking or other defects to ensure that the performance and reliability of the finished unit at least matches that of an original new engine. All engineering and quality management activities are audited and certified to ISO9001:2015.

Remanufacturing Standards

Dynamoter Facility

All engines are fully tested, with our in-house computerised dynamometer room providing detailed analysis and recording of all essential performance characteristics. After successful testing the engine is sealed, capped, masked and painted. Appropriate preservation fluids are added along with part serialisation information before packaging in accordance with requirements.

Experienced in engines for special applications, original equipment specifications are rigorously applied through controlled documents and assured build processes.

Dynamoter Facility

Comprehensive Testing

In line with customer requirements, every engine is fully tested against an agreed performance plan. Test parameters include:

- Power output at various rpm

- Torque output at various rpm

- Maximum power

- Maximum torque

- Oil temperature

- Coolant temperature

- Turbocharger boost pressure

- Manifold vacuum pressure

- Vibration

- Noise

- Gas emissions

- Particulate (smoke) emissions

The onsite dynamometer facilities are computer controlled and an electronic record is held for every test done.

Comprehensive Testing